System Maintenance: 7 Ultimate Secrets for Peak Performance

System maintenance isn’t just a tech chore—it’s the backbone of smooth, reliable operations. Whether you’re managing a server, a manufacturing line, or a personal computer, regular upkeep ensures longevity, efficiency, and fewer headaches down the road.

What Is System Maintenance and Why It Matters

At its core, system maintenance refers to the routine activities performed to keep systems—be they software, hardware, or a combination—running efficiently and reliably. These activities prevent failures, extend lifespan, and ensure optimal performance. Without proper system maintenance, even the most advanced technologies can degrade quickly, leading to costly downtime and security vulnerabilities.

Defining System Maintenance

System maintenance encompasses all actions taken to inspect, repair, upgrade, and optimize systems. This includes updating software, cleaning hardware components, monitoring performance metrics, and replacing worn-out parts. According to the ISO 14224 standard, maintenance is a critical part of asset management in industrial settings.

- Preventive actions to avoid breakdowns

- Corrective measures after a failure

- Adaptive changes due to evolving needs

These tasks apply across industries—from IT networks to HVAC systems and production machinery.

The Business Impact of Neglecting Maintenance

Ignoring system maintenance can lead to catastrophic consequences. A study by McKinsey & Company found that unplanned downtime costs industrial manufacturers an estimated $50 billion annually. In IT, outdated systems are prime targets for cyberattacks. For example, the 2017 WannaCry ransomware attack exploited unpatched Windows systems, affecting over 200,000 computers across 150 countries.

“An ounce of prevention is worth a pound of cure.” – Benjamin Franklin

This timeless quote perfectly encapsulates the value of proactive system maintenance.

The 4 Types of System Maintenance

Understanding the different types of system maintenance helps organizations choose the right strategy for their needs. Each type serves a unique purpose and is suited to different environments and risk profiles.

Corrective Maintenance

Corrective maintenance, also known as reactive maintenance, is performed after a system fails. It involves diagnosing the issue, repairing or replacing faulty components, and restoring functionality.

- Common in low-criticality systems

- Cost-effective for non-essential equipment

- Risky for mission-critical operations

While this approach requires minimal planning, it often results in longer downtimes and higher long-term costs.

Preventive Maintenance

Preventive maintenance is scheduled upkeep designed to prevent failures before they occur. This includes regular inspections, lubrication, calibration, and part replacements based on time or usage.

- Reduces unexpected breakdowns

- Extends equipment life

- Improves safety and compliance

For example, data centers perform monthly checks on cooling systems to prevent server overheating. The Society for Maintenance & Reliability Professionals (SMRP) recommends preventive strategies for high-availability environments.

Predictive Maintenance

Predictive maintenance uses real-time data and analytics to predict when a system will fail. Sensors monitor parameters like vibration, temperature, and pressure to detect anomalies before they escalate.

- Leverages IoT and machine learning

- High initial investment but strong ROI

- Used in aviation, energy, and manufacturing

General Electric uses predictive analytics on jet engines to forecast maintenance needs, reducing flight delays and repair costs.

Perfective and Adaptive Maintenance

Perfective maintenance improves system performance or usability, while adaptive maintenance modifies systems to accommodate changes in the environment—such as new regulations or software updates.

- Perfective: Optimizing code for faster response times

- Adaptive: Updating software to comply with GDPR

- Both enhance long-term system relevance

These types are especially crucial in software development and IT infrastructure.

Key Components of Effective System Maintenance

A successful system maintenance program isn’t just about fixing things—it’s about building a structured, repeatable process. Several key components must be in place to ensure consistency and effectiveness.

Asset Inventory and Tracking

You can’t maintain what you can’t track. A comprehensive asset inventory lists all hardware, software, and network components, including serial numbers, installation dates, warranty information, and maintenance history.

- Enables accurate scheduling

- Supports lifecycle management

- Facilitates audit and compliance

Tools like ServiceNow IT Asset Management help automate this process, reducing human error.

Maintenance Scheduling and Planning

Effective scheduling ensures that maintenance tasks are performed at optimal times—minimizing disruption to operations. This involves creating calendars, assigning responsibilities, and setting priorities.

- Use CMMS (Computerized Maintenance Management Systems)

- Align with production cycles

- Include buffer time for unexpected issues

For instance, hospitals schedule maintenance on medical imaging devices during off-peak hours to avoid interfering with patient care.

Documentation and Reporting

Detailed records of all maintenance activities are essential for accountability, analysis, and continuous improvement. Reports should include what was done, who did it, when, and any findings or recommendations.

- Supports root cause analysis

- Helps justify budget requests

- Required for ISO and regulatory compliance

Well-documented system maintenance logs can reduce repeat failures by up to 30%, according to research published in the Journal of Quality in Maintenance Engineering.

Best Practices for System Maintenance in IT

In the digital world, system maintenance is vital for data integrity, security, and performance. IT teams must follow best practices to keep networks, servers, and applications running smoothly.

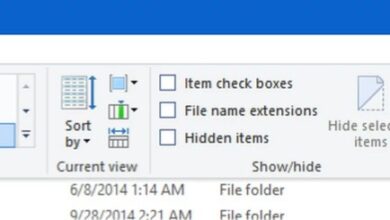

Regular Software Updates and Patch Management

One of the most critical aspects of IT system maintenance is keeping software up to date. Patches fix security vulnerabilities, improve performance, and add new features.

- Enable automatic updates where possible

- Test patches in a staging environment first

- Prioritize critical security updates

The U.S. Cybersecurity and Infrastructure Security Agency (CISA) maintains a Known Exploited Vulnerabilities (KEV) catalog, urging organizations to patch listed vulnerabilities within strict deadlines.

Data Backup and Recovery Testing

No system maintenance plan is complete without a robust backup strategy. Regular backups protect against data loss from hardware failure, cyberattacks, or human error.

- Follow the 3-2-1 rule: 3 copies, 2 media types, 1 offsite

- Automate backup schedules

- Test recovery procedures quarterly

According to Veeam’s 2023 report, 76% of organizations experienced data loss in the past year—many due to inadequate backup testing.

Network Monitoring and Performance Tuning

Continuous monitoring allows IT teams to detect issues before users notice them. Tools like Nagios, PRTG, and SolarWinds provide real-time insights into network health.

- Monitor bandwidth, latency, and uptime

- Set up alerts for unusual activity

- Optimize configurations for peak performance

Proactive network system maintenance can reduce outage duration by up to 50%, per Gartner research.

System Maintenance in Industrial and Manufacturing Environments

In heavy industries, system maintenance is a matter of safety, productivity, and regulatory compliance. Equipment failure can halt production lines, endanger workers, and result in massive financial losses.

Maintenance of Machinery and Production Lines

Manufacturing plants rely on complex machinery that requires regular lubrication, alignment, and calibration. A single malfunctioning conveyor belt can disrupt an entire assembly line.

- Use vibration analysis to detect bearing wear

- Inspect belts, gears, and motors weekly

- Train operators in basic troubleshooting

Toyota’s Total Productive Maintenance (TPM) model empowers every employee to participate in equipment upkeep, significantly reducing downtime.

Safety Protocols and Compliance Standards

Industrial system maintenance must adhere to strict safety regulations. OSHA (Occupational Safety and Health Administration) and ISO standards mandate regular inspections and documentation.

- Lockout/Tagout (LOTO) procedures during maintenance

- Annual safety audits

- Employee training on hazard recognition

Failure to comply can result in fines, legal action, and workplace injuries.

Integration with Supply Chain Management

Maintenance doesn’t happen in isolation. Spare parts, tools, and technician availability must be coordinated with supply chain logistics.

- Maintain a buffer stock of critical components

- Partner with reliable vendors

- Use ERP systems to synchronize maintenance and procurement

Siemens uses AI-driven supply chain analytics to predict part failures and pre-position replacements, minimizing machine idle time.

Emerging Technologies Transforming System Maintenance

The future of system maintenance is smarter, faster, and more predictive than ever. New technologies are revolutionizing how organizations monitor and maintain their systems.

Artificial Intelligence and Machine Learning

AI-powered systems analyze vast amounts of operational data to detect patterns and predict failures. Machine learning models improve over time, becoming more accurate with each cycle.

- AI can predict hard drive failures with 90%+ accuracy

- Used in predictive maintenance for wind turbines

- Reduces false alarms in monitoring systems

Google’s DeepMind has been used to optimize data center cooling, cutting energy usage by 40%—a form of intelligent system maintenance.

Internet of Things (IoT) and Real-Time Monitoring

IoT devices embed sensors into equipment, enabling continuous monitoring of temperature, pressure, vibration, and more. This data is streamed to dashboards for real-time analysis.

- Smart sensors in elevators predict cable wear

- Connected HVAC systems auto-adjust based on usage

- Remote diagnostics reduce on-site visits

According to Statista, the number of IoT devices will exceed 29 billion by 2030, driving a surge in connected maintenance solutions.

Digital Twins and Simulation

A digital twin is a virtual replica of a physical system. Engineers can simulate maintenance scenarios, test upgrades, and optimize performance without disrupting real-world operations.

- Used in aerospace for engine testing

- Helps plan complex overhauls

- Trains technicians in virtual environments

NASA uses digital twins to maintain spacecraft systems, allowing them to troubleshoot issues millions of miles from Earth.

How to Build a System Maintenance Plan

A well-structured system maintenance plan is essential for consistency, accountability, and long-term success. It should be tailored to your organization’s size, industry, and risk tolerance.

Assessing System Criticality and Risk

Not all systems are equally important. Begin by classifying assets based on their impact on operations, safety, and revenue.

- High-criticality: Servers, emergency systems

- Medium: Office printers, secondary networks

- Low: Non-essential peripherals

This prioritization helps allocate resources effectively and focus on what matters most.

Setting Maintenance Goals and KPIs

Clear goals turn maintenance from a cost center into a performance driver. Key Performance Indicators (KPIs) should be measurable and aligned with business objectives.

- Mean Time Between Failures (MTBF)

- Mean Time to Repair (MTTR)

- Overall Equipment Effectiveness (OEE)

For example, a goal might be to increase MTBF by 20% within a year through improved preventive maintenance.

Training and Empowering Maintenance Teams

Even the best tools are ineffective without skilled personnel. Invest in ongoing training and foster a culture of ownership and accountability.

- Provide certifications (e.g., CMRP, CompTIA)

- Encourage cross-training between IT and operations

- Recognize and reward proactive maintenance behavior

Empowered teams are more likely to identify issues early and suggest process improvements.

What is the most important type of system maintenance?

Preventive maintenance is often considered the most important because it stops failures before they happen. While corrective maintenance is necessary, relying on it leads to higher costs and downtime. Preventive strategies offer the best balance of cost, reliability, and safety.

How often should system maintenance be performed?

The frequency depends on the system type and usage. Critical IT systems may require daily monitoring and monthly updates, while industrial machinery might need weekly inspections and annual overhauls. Always follow manufacturer guidelines and industry best practices.

Can system maintenance be automated?

Yes, many aspects of system maintenance can be automated. Software updates, backups, and network monitoring can be scheduled and managed through tools like Ansible, Puppet, or Microsoft Endpoint Manager. Predictive maintenance systems use AI to automate failure detection and alerting.

What are the costs of poor system maintenance?

Poor system maintenance leads to increased downtime, higher repair costs, reduced productivity, security breaches, and potential safety hazards. In extreme cases, it can result in regulatory fines or reputational damage.

Is system maintenance the same as system repair?

No. System maintenance is a proactive, ongoing process to keep systems running smoothly. System repair is reactive—it happens after a failure. Maintenance includes repair as one component, but also covers prevention, optimization, and upgrades.

System maintenance is far more than a technical checklist—it’s a strategic discipline that safeguards performance, security, and sustainability. From preventive routines in IT to predictive analytics in manufacturing, effective maintenance practices are evolving with technology. By understanding the types, components, and best practices of system maintenance, organizations can reduce costs, extend asset life, and ensure uninterrupted operations. The future belongs to those who maintain not just to fix, but to optimize and innovate.

Further Reading: